The Flexi-Rex is one of my favorite 3D prints to make and give away. It shows the incredible things you can do with the process like fully-formed assemblies with articulating parts in a fun dinosaur shape!

Why not combine my current obsession with my favorite print? I searched around to see if anyone has done it and was fairly surprised to see nothing out there. Surely with all the others doing metal casting out there someone should have done it, right? Well, I guess I’m making that someone me.

I could tell that this would be a challenge for casting. Luckily I have access to a makerspace and its investment casting equipment, which is perfect for doing intricate castings and works with the lost PLA casting process.

Attempt #1

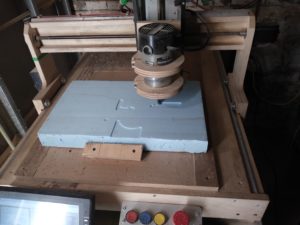

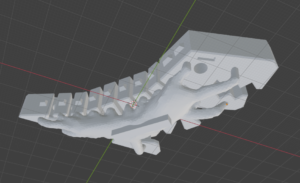

I took the original 3D model and designed a secondary structure to attach to it. Essentially it is the network of feed sprues that will carry the metal to each segment. It looks like that weird sculpture from Beetlejuice. I went through a couple iterations of this till it seemed right (and fit the casting flasks available to me), and decided to give it a go.

I decided to put two into the biggest flask available, hoping to increase my chances of at least one filling. Little did I realize that probably hurt more than it helped. I needed to fill much more volume with metal, which wound up with me scrambling as I didn’t have quite enough scrap on hand and I had a barely large enough crucible to fill it.

When casting day came, I thought I was prepared but I made a few errors that resulted in it not filling fully.

Most of what filled is the support structure leading to the part, so the actual parts of the 3D print that filled were just a head and neck segment. Even thought it’s technically a failed casting, I absolutely kept the bronze head. I’m a sucker for carrying around a small shiny object.

Things that went well:

- The mold and burnout process went flawlessly. Attaching the 3D prints to the wax sprue was tricky but worked well.

- The melt went well.

Mistakes made:

- Did not use the right gasket and adapter plate, so it never pulled a full vacuum.

- Did not prepare enough metal and had to scramble to cut more pieces to fit the crucible.

- Allowed the mold to cool lower than ideal temp. I turned off the kiln when I was getting ready to cast,, but it took longer to prepare than I planned.

- Possibly overheated the metal. There were a lot of dark crumbs on top, unclear if they were impurities, graphite from the crucible, or metals in the bronze coming out of solution.

Attempt #2

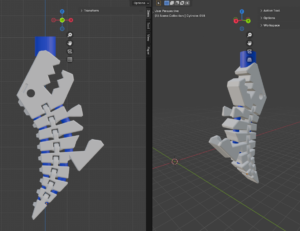

The previous version basically only filled the structure I created to feed metal into the model, so I decided to redesign that to require much less material. The sections are now joined together through little sprues next to each segment, which should allow the metal to flow through each segment to the bottom and fill everything more directly. This will be also a vacuum assisted casting, so any air should be pulled out through the plaster.

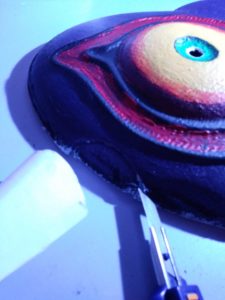

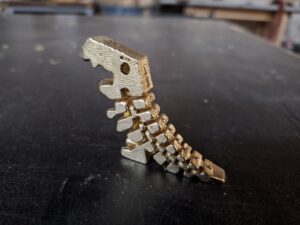

This ultimately went much better! I made two separate molds hoping that I’d have a better chance at success if one mold was messed up. Almost a complete fill on both, but still some gaps. You can see in some areas where the pin and shackle connections don’t exist, particularly close to the head. The tail section may or may not have complete links, but rather than cut it apart to find out I decided to keep it intact as a statue.

I cleaned up the most complete one and polished it up. This was so satisfying to get to this point, and is that much closer to a fully metal, fully flexi flexi-rex.

The places where it is missing material are somewhat strange, but probably relate to how the vacuum is being pulled on the mold. The flask only had an opening on the bottom where the tail was, and for the most part that filled the best. There are other flasks that have perforations in the side to allow the vacuum to pull from almost all sides, which may be a better fit for such a complicated shape with intertwined pieces.

Attempt #3

After some minor tweaks to the 3D model, I was ready to try again. The areas on the previous version where metal seemed to have to climb uphill were an issue, so I added some tubes to connect those areas so the metal would flow through there.

To make things easier I also used a lower temp metal, so I chose some aluminum scrap we had saved up at the shop. It was primarily scrap from computer fan heatsinks, which I understand to be not ideal for casting. However with vacuum casting it doesn’t seem to be an issue.

Before this pour I went through all the motions to make sure I didn’t miss a step (like checking the vacuum seal), and I had two flasks lined up in case the first one went wrong. Everything went perfect!

They look so perfect! No voids, no warts, and the texture is pretty much all there. As good as it looks though, its a mystery how good the inner links are since its pretty small in there. I’d have to cut the little connector tubes betweem each piece to find out. A jeweler’s saw is thin enough to get between the pieces, so I put it in a vice and cut away. I could tell after cutting just one that it was looking good.

After cutting all the links and cleaning up some of the sections…

Folks, we have an all-metal Flexi Rex. It’s pretty incredible how exact everything seems to be, it feels just like the original 3D print. It’s possibly even lighter than the plastic one due to the aluminum, and the segments move really smooth due to it having less friction than plastic. I am absolutely thrilled that it worked so flawlessly, and I hope to see others try this out!